The Wood2Wood consortium meeting concluded on a high note in Brussels on September 17, bringing together valuable insights on the latest technological advancements, encouraging feedback from European Commission reviewers and a clear outlook on the path ahead. Hosted by consortium partner Centre for European Policy Studies (CEPS) at their premises, the Month 18 review meeting was a chance to showcase project progress across all work packages and pillars of innovation. Most importantly, the meeting was an opportunity to meet consortium members in person and strengthen interpersonal bonds. After all, consortium meetings are more than just a knowledge sharing exercise on technical innovations; it is about building social connections.

Camaraderie and team spirit was on full display in Brussels as Work Package (WP) leaders presented their progress updates with the full support and guidance of task leaders.

Steady progress has been made across all six objectives, including the WPs.

Objective 1

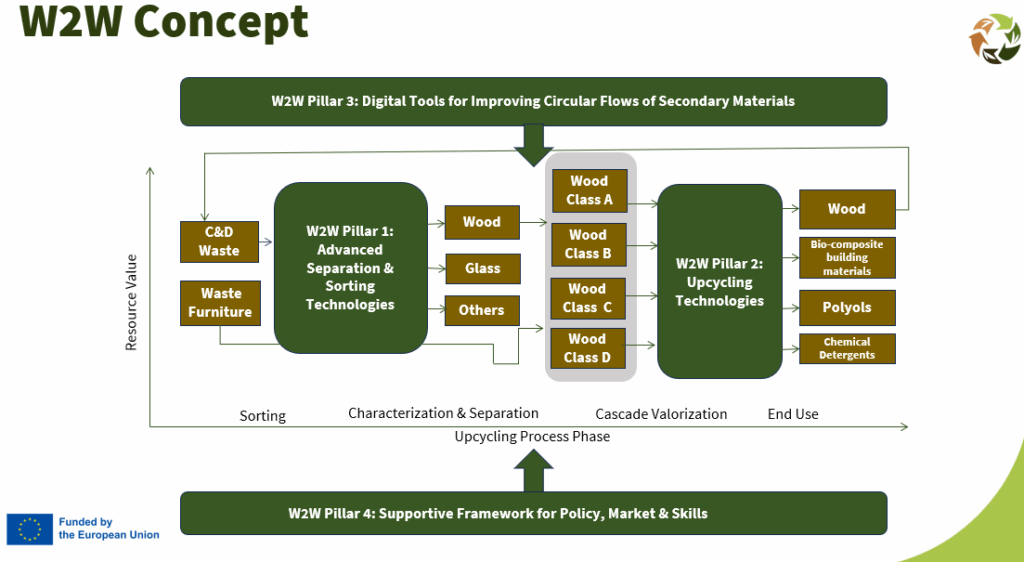

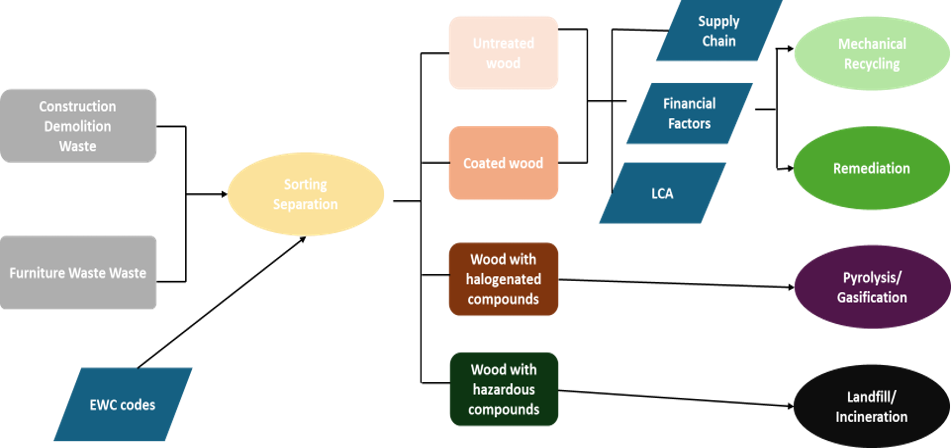

We’ve developed and tested the first version of cascade valorisation framework with real data, mapped relevant stakeholders and established a harmonised EU-wide waste wood classification. In the coming months, we will enhance and finalise the cascade valorisation framework based on the harmonised classification scheme.

Objective 1 M18 updates

- Developed and tested the first version of cacascade valorisation framework with real data.

- Mapped relevant stakeholders.

- Established a harmonised EU-wide waste woodclassification.

- Next RP: Deliver the final W2W framework based on the harmonised classification scheme.

Objective 2

To improve separation capabilities of wood sorting mechanisms the project has developed the digital MFA tool on pilot data, which will potentially enable higher recycling rates and profitability with enhanced sorting. In addition, the Work Package leader also designed the adaptive glass/wood sorting system, a cobot station (human-robot collaboration) and prototyped the Mixed Reality support system. Next step is to upgrade the TRL5 (Technological Readiness Level) prototypes, including sorting, robotics and XR, to TRL6 demo.

Objective 2 M18 updates

- Digital MFA tool on pilot data: higher recycling rates & profitability with enhanced sorting.

- Adaptive glass/wood sorting system designed; cobot station & MR support prototyped.

- Next RP: TRL5 prototypes will be upgraded (sorting, robotics, XR) to TRL6 demo; ICCS will operate a pilot-scale adaptive sorting line with higher feedstock volumes.

Objective 3

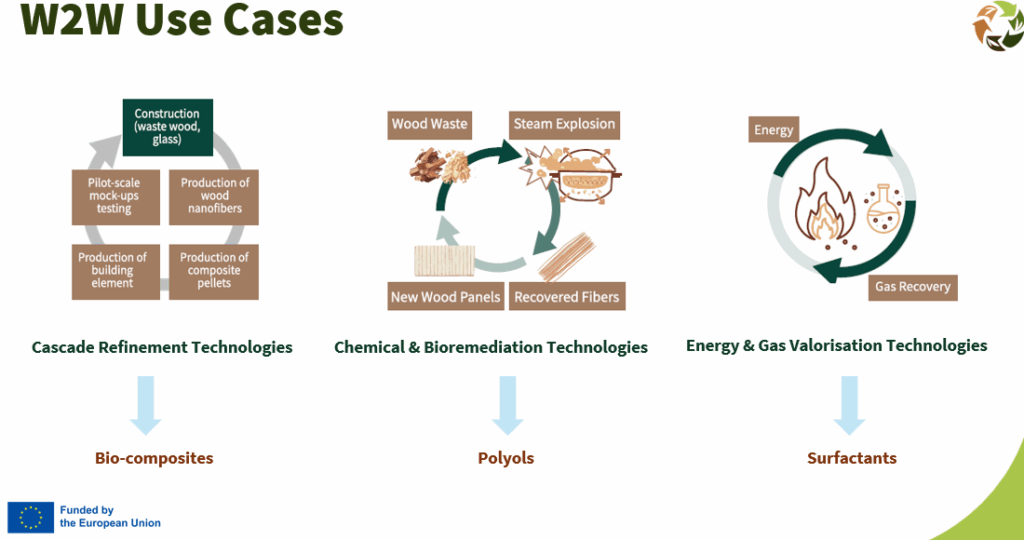

An important part of the project’s innovation involves the development of sustainable and innovative technologies for upcycling waste materials to promote resource efficiency and reduce waste for sustainable waste management. This process involves cascade refinement, chemical and bioremediation processes along with energy, gas and ashes valorisation in cases where material recovery is not possible. The end result is to ensure that the secondary materials retrieved through the processes have good and consistent quality and are safe to use for upcycling.

On this front, some progress has been achieved, including extraction of nanofibers and lignin from wood waste. Additionally, PLA biocomposites and facade panel prototypes have been produced. To remove contaminants, such as residual glue, from the surface of wood fibres, steam explosion process is used to make recycling easier. Until M18, steam explosion has been scaled to TRL5 for glue removal. Following this, through fungal bioremediation process, effluents present in hazardous wood waste have been detoxified. In the Energy, gas and ashes valorisation process, hydrothermal carbonisation and gasification processes have been optimised yielding high hydrochar (solid, carbon-rich material) and efficient hydrogen production. Finally, pilot gas fermentation of syngas has been advanced and first fatty alcohol samples have been delivered to P&G for validation.

Objective 3 M18 updates

- Nanofibers and lignin extracted from wood waste; PLA biocomposites and façade panel prototypes produced.

- Steam explosion scaled to TRL5 for glue removal; fungal bioremediation detoxified effluents; bio-based polyols and first NIPU adhesives synthesised.

- Hydrothermal carbonisation and gasification optimised, yielding high hydrochar and efficient hydrogen production.

- Pilot gas fermentation of syngas advanced; first fatty alcohol samples delivered to P&G for validation

Objective 4

To support our technical innovations, the project is developing digital tools to help integrate life cycle thinking and sustainability assessment throughout the cascade process. Digital tools are critical to track the impact of our technologies over several material use cycles. The digital tools include Life cycle assessments, Digital Product Passports (DPPs), Material Volume estimation, and a Supply Chain Optimisation Tool.

Objective 4 M18 updates

- Functional versions of digital tools released including DPP, Material Volume Estimation, Supply Chain Optimisation, LCSA.

- Initial architecture of Integrated Circular Wood Upcycling Platform completed.

- Next RP: final tools released, Platform fully functional.

Objective 5

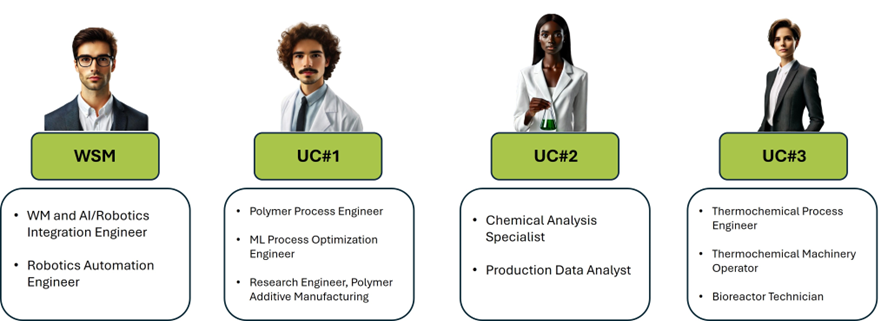

The project results will ultimately be used to demonstrate efficient and sustainable value chains in 3 Use Cases to produce wood without pollutants, biocomposite building materials, biopolymers, polyols, and chemical detergents. In addition, the recovery of nutrients will be implemented using technologies and tools that allow the selection of optimal cascade paths for further uses of wood products and their materials.

Objective 5 M18 updates

- Initial validation of technologies/solutions in the 3 Use Cases completed as final tasks of each WP.

- Validation will continue in the next period for TRL6 technologies.

- In WP15 (M36–48), activities will support sustainable supply chains and validate the overall cascade valorisation scheme.

Click on these links to watch our Use Case videos (Use Case 1, Use Case 2 and Use Case 3)

Objective 6

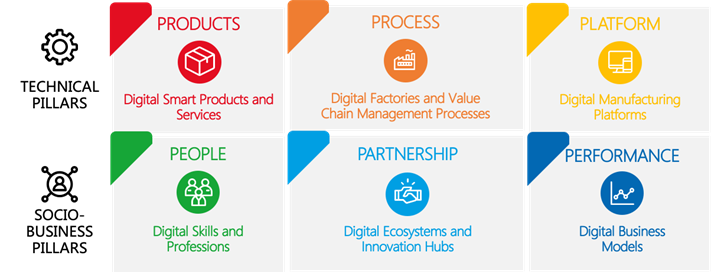

Finally, W2W will enhance competitiveness and promote sustainable practices in industries through skills development, collaborative training programs, capacity building, contributions to standards and certification schemes, policy influence, and business models in circular and sustainable processes.

Objective 6 M18 updates

- Policy recommendations for waste wood valorisation (DPPs).

- Signal analysis: wood tech, sustainability, digital.

- Emerging role profiles from expert workshops.

- Next RP: Leverage report with policy insights for valorisation & W2W DPP, plus list of relevant standards; Expanded training catalogue, surveys, workshop, feedback.

Visit our Skills Development page to see the detailed work by POLIMI. Relatedly, also view our Trends, Signals and Occupational Scenarios page developed in collaboration with VTT.

Summary

Taken together, W2W project hopes to reduce the demand for virgin materials, reduce the amount of waste that ends up in landfills or incineration facilities, allow for the creation of new value-added products from waste materials, and support the transition towards a circular economy by promoting closed-loop systems where materials are continually repurposed and reused, extending their useful life.

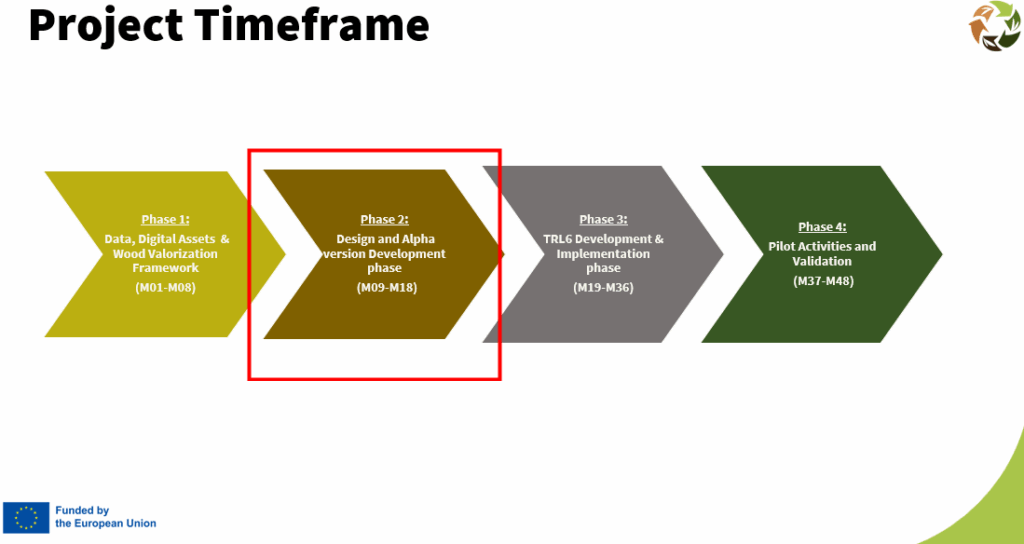

The review meeting was a good stocktaking exercise to measure project progress against Key Performance Indicators (KPIs) across all work packages. The feedback from reviewers will inform the next phase (M18-M36) of project developments.