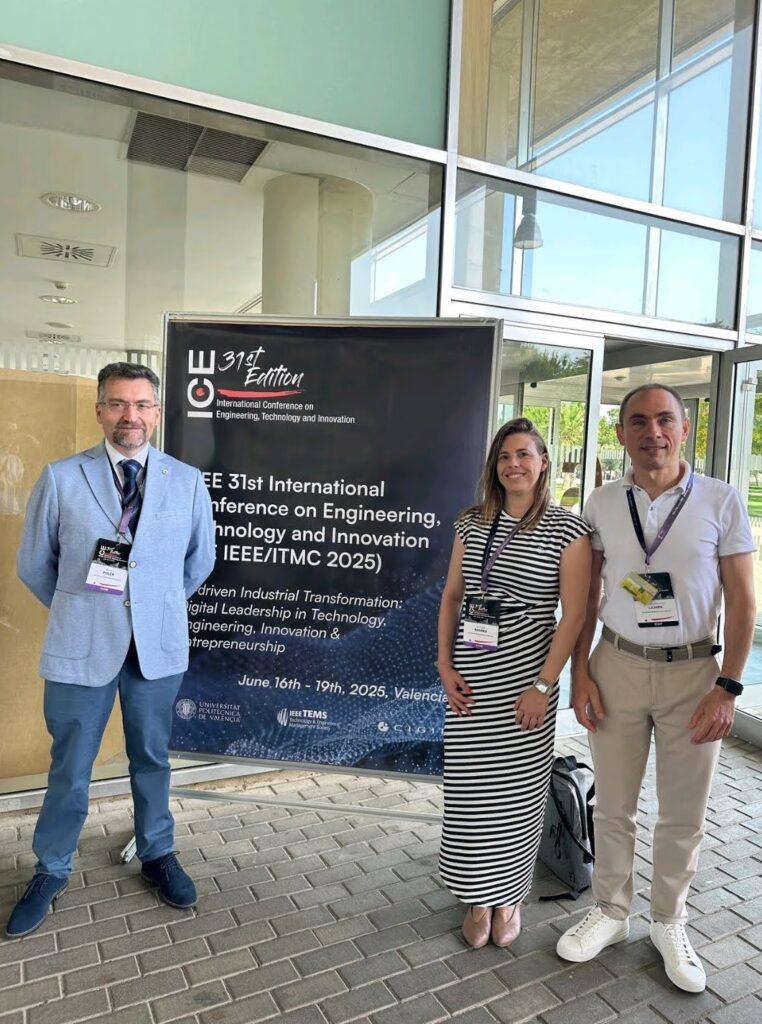

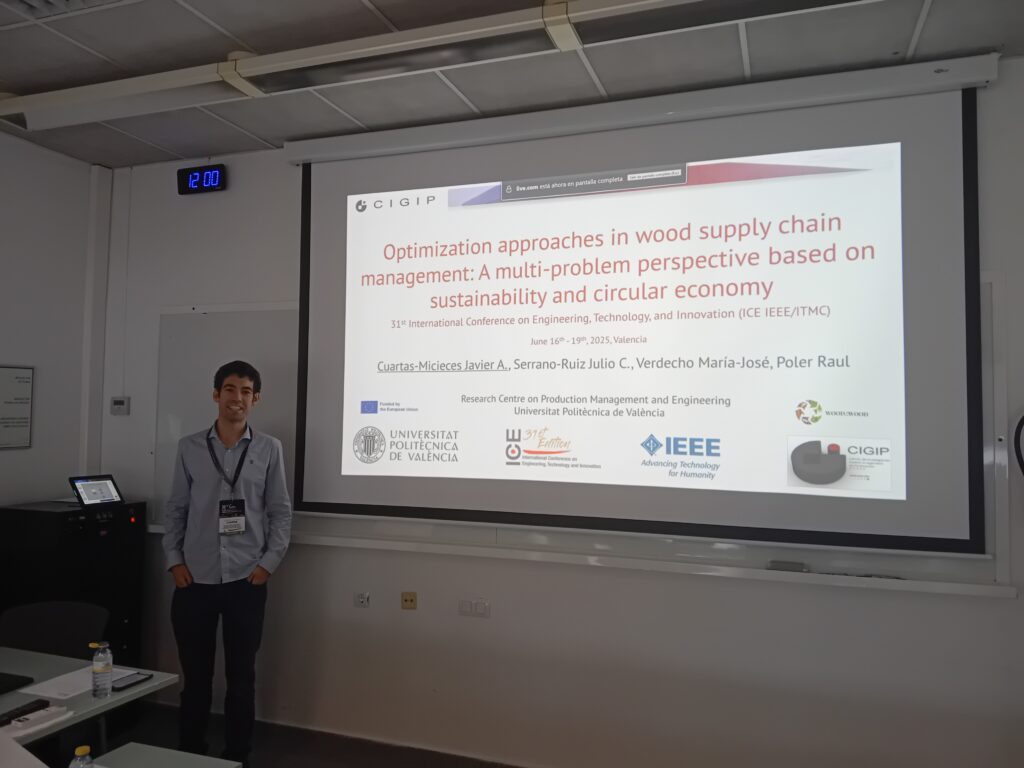

Recently, one of our consortium partners in the project, CIGIP-UPV, presented their contributions in the Wood2Wood project at ICE/IEEE ITMC held in Valencia, Spain. Javier Cuartas, Raul Poler and José Antonio Comesaña Benavides presented two conference papers at ICE 2025 on “𝑶𝒑𝒕𝒊𝒎𝒊𝒛𝒂𝒕𝒊𝒐𝒏 𝑨𝒑𝒑𝒓𝒐𝒂𝒄𝒉𝒆𝒔 𝒊𝒏 𝑾𝒐𝒐𝒅 𝑺𝒖𝒑𝒑𝒍𝒚 𝑪𝒉𝒂𝒊𝒏 𝑴𝒂𝒏𝒂𝒈𝒆𝒎𝒆𝒏𝒕”.

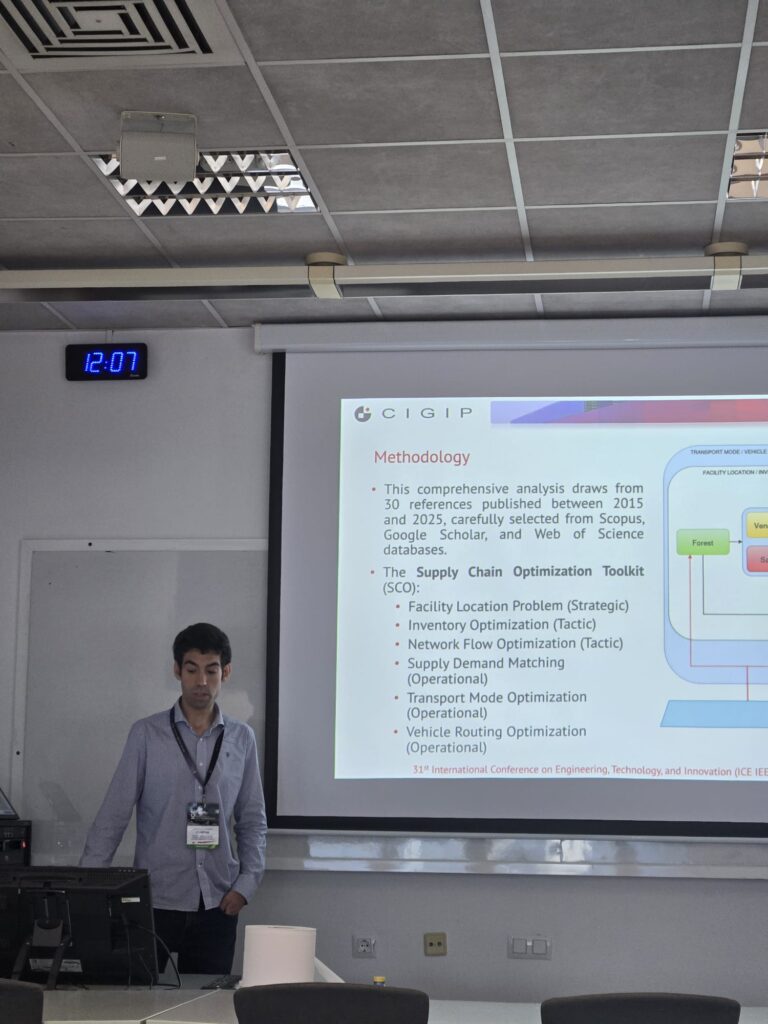

➡️𝐎𝐩𝐭𝐢𝐦𝐢𝐳𝐚𝐭𝐢𝐨𝐧 𝐀𝐩𝐩𝐫𝐨𝐚𝐜𝐡𝐞𝐬 𝐢𝐧 𝐖𝐨𝐨𝐝 𝐒𝐮𝐩𝐩𝐥𝐲 𝐂𝐡𝐚𝐢𝐧 𝐌𝐚𝐧𝐚𝐠𝐞𝐦𝐞𝐧𝐭: A Multi-Problem Perspective Based on Sustainability and Circular Economy.

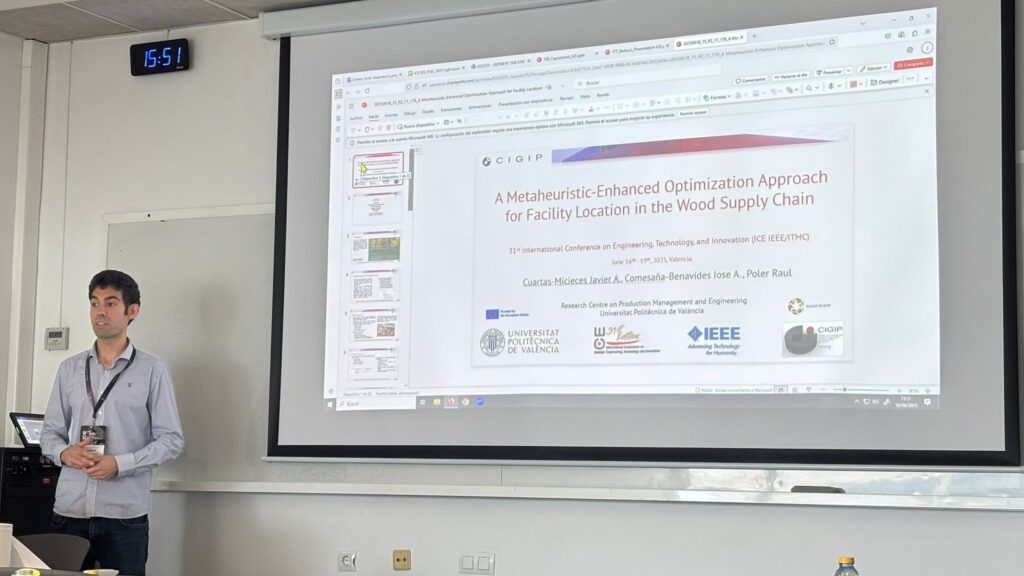

➡️𝐎𝐩𝐭𝐢𝐦𝐢𝐳𝐚𝐭𝐢𝐨𝐧 𝐀𝐩𝐩𝐫𝐨𝐚𝐜𝐡𝐞𝐬 𝐢𝐧 𝐖𝐨𝐨𝐝 𝐒𝐮𝐩𝐩𝐥𝐲 𝐂𝐡𝐚𝐢𝐧 𝐌𝐚𝐧𝐚𝐠𝐞𝐦𝐞𝐧𝐭: Facility Location Problem, A Metaheuristic-Enhanced Approach

In the first paper, authors Javier Cuartas Micieces, Raul Poler and José Antonio Comesaña Benavides from CIGIP-UPV expand on how advanced optimisation techniques can enhance economic, environmental, and social performance across the wood supply chain — from routing and transport modes to inventory and facility location.

📊 What makes this paper unique?

The authors analysed the multiple optimisation challenges as 𝐢𝐧𝐭𝐞𝐫𝐜𝐨𝐧𝐧𝐞𝐜𝐭𝐞𝐝 𝐝𝐞𝐜𝐢𝐬𝐢𝐨𝐧 𝐩𝐫𝐨𝐛𝐥𝐞𝐦𝐬 with trade-offs involved and 𝐍𝐎𝐓 in isolation.

In the second paper, the same authors tackle one of the most complex supply chain challenges — “𝐟𝐚𝐜𝐢𝐥𝐢𝐭𝐲 𝐥𝐨𝐜𝐚𝐭𝐢𝐨𝐧” — using advanced metaheuristics, developing a model to reduce total system costs and improve decision-making in large-scale, dynamic environments.

Within this paper, future directions will include:

➡️Integrating real-time analytics,

➡️Machine learning, and

➡️Multi-objective optimisation frameworks to enhance adaptability and sustainability in facility location decision-making.

Both the presentations mark the start of R&D efforts for developing the 𝐖𝟐𝐖 𝐒𝐮𝐩𝐩𝐥𝐲 𝐂𝐡𝐚𝐢𝐧 𝐎𝐩𝐭𝐢𝐦𝐢𝐬𝐚𝐭𝐢𝐨𝐧 𝐃𝐢𝐠𝐢𝐭𝐚𝐥 𝐓𝐨𝐨𝐥, a key part of our ongoing commitment to sustainable and circular logistics.

💡What will be the added benefit of the Supply Chain Optimisation Digital Tool beyond the project?

➡️Companies can use this tool to design, simulate, and optimise their supply chain networks for secondary materials by creating virtual representations of their supply chains for the secondary materials providers, recyclers, transporters, formulators and users.