Many know Rimini in Italy as a popular summer tourist destination with one of the longest sandy coastlines in Europe. But while that reputation is well deserved, every year in November the coastal city transforms into an ideation hub on circularity. Innovators, visionary EU-funded projects, companies, start-ups, researchers, and policymakers meet at the Ecomondo Green Technology exhibition for ecological transitions to explore avenues to transform their cross-sectoral ideas and initiatives into practice.

Rimini holds a special place for the International Solid Waste Association (ISWA), a global not-for-profit association that promotes sustainable waste and resource management. Each year the expo provides ISWA with a valuable platform to showcase the association’s work through a dedicated booth and to host a range of activities focused on sustainable waste and resources management for its global membership base spanning over 115 countries. Other than catering to our members, ISWA also organises a workshop specifically for EU-funded projects for which the association is proud to act as the technical communication and dissemination partner.

Last year, W2W participated in a workshop alongside three other Horizon Europe projects on sustainable waste management and material recovery, namely RECLAIM, Grinner Project and EcoRefibre.

This year’s Ecomondo expo was another special moment to celebrate the results from these EU-funded projects on Research and Innovation to support circular transitions in Europe. For this year’s edition, four Horizon EU projects Wood2Wood, EcoRefibre, CircuLess, ReBoat and BIO4EEB came together to share cross-sectoral knowledge on sustainable waste and resource management and digital solutions in areas like plastics, textiles and wood waste derived from construction and demolition and furniture waste.

The theme of this year’s EU projects workshop was “Driving the Circular Transition in the EU: Recovering Value from Secondary Raw Materials”. The workshop’s objective was to drive progress towards a circular economy by keeping materials in circulation for as long as possible to reduce European dependence on virgin resources and build resilience to de-risk its supply chain in the face of global supply chain uncertainties.

The workshop was aimed not only at the participating projects but also accessible for policymakers, researchers, industry and civil society participants who were at Ecomondo. Interestingly, the workshop was attended by the target audiences that we hoped for, such as NGOs, researchers working on innovation in circularity, waste recycling industry, not-for-profit organisations like Zero Waste Alliance of Ireland, persons from media, a trade compliance consultancy, sports retail and textiles and fisheries industry, among others. The word cloud from our Slido poll reflects the same but also, crucially, highlights what these audiences were interested in unpacking at the workshop: Viability of secondary raw materials, recovery and recycling of secondary raw materials, data model that these projects are using to enhance circularity objectives.

How to address Construction and demolition waste, EU’s largest waste stream

All projects represented different sectors, from wood waste (Wood2Wood, EcoRefibre, Circuless, BIO4EEB) to plastics and textiles (ReBoat and Circuless). But the objective was the same: how do we efficiently and effectively recover value from secondary raw materials to accelerate circularity in the EU.

Wood2Wood project

Let us start with the Wood2Wood Project that wants to develop novel upcycling and recycling solutions for the wood waste derived from the construction and demolition and furniture industries. In order to implement their solutions the project proposes a comprehensive framework for multi-dimensional cascade valorisation of wood from C&D and furniture waste, consisting of four core components/pillars:

1) Advanced separation and sorting technologies;

2) Upcycling processes and technologies;

3) Digital tools for improving circular flows of secondary materials;

4) Supportive framework in policy, market, and skills.

The challenge and opportunity in front of them is significant, considering that construction and demolition waste accounts for a third of all waste generated in the EU in terms of volume. This is the bloc’s single largest waste stream. Despite this, most of this material with sizeable quantities of biomass like wood waste embedded in them, ends up being incinerated for energy recovery or sent to landfills.

Alessandro Pracucci from Levery, one of Wood2Wood’s consortium partners, represented the project at the workshop and took the audience through our multi-pronged approach using advanced sorting systems, innovative processing techniques that separate lignin and cellulose nanofibers, and the creation of new panel products, including solid and honeycomb panels suitable for use as façade materials.

First and foremost, design for recycling is key, said Pracucci. The most critical question for him is whether panel products can be reused once removed. According to Pracucci, products today are extremely complex and designed for safety and comfort, and little thought has gone behind its reuse potential.

“Key part is to close the loop of circularity aspect of wood, starting from the wood recovery to the wood panel with new processes. The objective of the project is to introduce a new circularity approach from all the wood value chain stakeholders,” he added.

Detailed version of his story can be found in Waste Management World magazine.

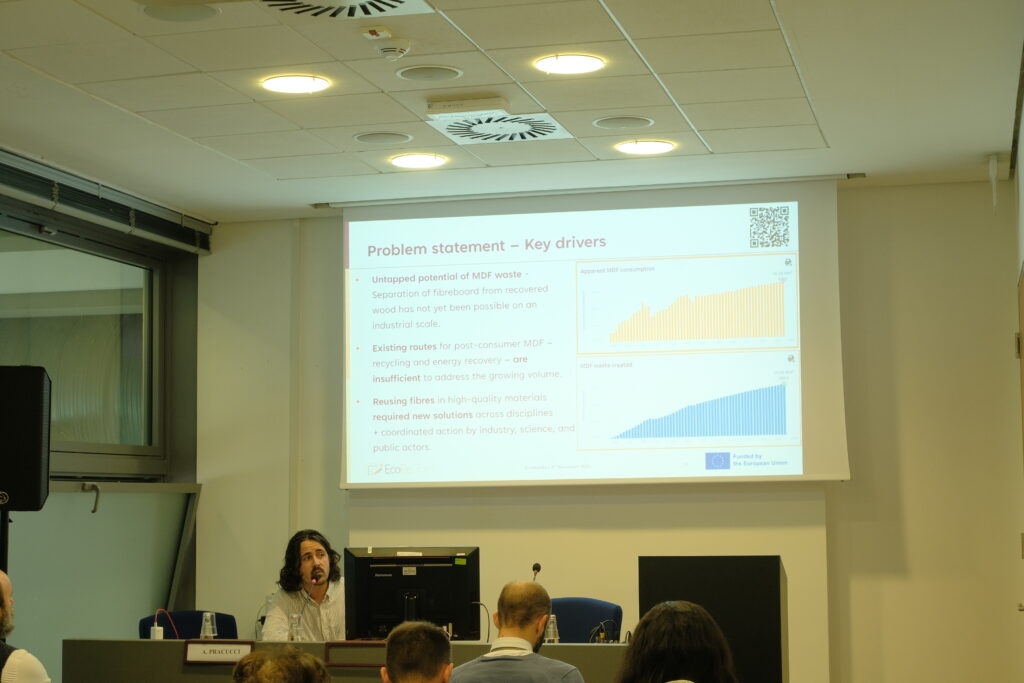

Exploring potential of Medium-density fibreboard (MDF)

EcoRefibre project steps in to identify a huge problem: MDF waste.

The challenge is very clear but complex: Europe has generated over 60 million tonnes of fibreboard in the last five years but most of this waste has been sent to incinerators for energy recovery, explained Duarte Carvalho of the European Panel Federation and Omar Degoli of FederlegnoArredo, both part of the EcoRefibre project.

Responding to this challenge, the project has developed state-of-the-art sorting lines and extraction techniques to recover fibres and fines from post-consumer MDF. The project intends to substitute up to 25 percent of virgin fibres currently being used in the European fibreboard manufacturing.

The project representatives present at the workshop identified three key areas of intervention: “firstly, we need reliable feedstock for scaling up, secondly, improve waste stream quality and finally, ensure policy alignment to privilege material recovery over premature energy recovery”.

Beyond buildings: Rethinking mineral and timber together

CircuLess project also aims to support circularity in the construction and demolition and manufacturing process industries by minimising construction and demolition and manufacturing waste (C&DMW) but focuses on mineral (concrete) and timber-based material streams. Digital tools underpin the project’s main objectives to support circularity by providing stakeholders access to reliable information on materials and training courses to equip them for the transition towards a circular economy.

“Waste timber is mostly incinerated but has great recycling potential,” informed Sotirios Grammatikos representing CircuLess project. But the question is how can people take informed decision when faced with waste from timber or concrete? “Our digital waste management platform can provide support to industry especially when faced with such complex questions,” he answered.

CircuLess project is developing digital tools to enhance circularity, but Grammatikos underlines that know-how to use the tools are important. Moreover, “cross collaboration is key supported by standardisation along with the early involvement of end-users and designers to improve outcomes,” he added.

Recycling on a boat to solve islands’ seasonal waste surge

Come summer, popular island destinations brim with tourists and digital nomads. As a result, waste generation also increases. This seasonal spike in waste generation poses a challenge to local municipalities who are often not equipped to handle this waste. ReBoat project offers a novel solution to a persistent problem: A mobile recycling plant on a boat, turning plastics and textiles into new products. This mobile plant can travel to islands during peak tourist seasons and handle waste on-site.

“It’s a tourism-focused project with the intention to improve the sustainability of tourism and address waste management challenges of islands during peak tourism season,” explained Omar Maschi from Centrocot, a consortium partner representing ReBoat project at the workshop.

What sets ReBoat apart from the other projects is its strong focus on community engagement and co-creation with local stakeholders. The project will implement pilot cases in three locations including Greece’s Ionian Islands, Italy’s Aeolian Islands, and Portugal’s Azores.

“We are looking at ways to replicate this system in other places,” noted Maschi, emphasising the project’s potential to be replicated in remote areas globally that face seasonal waste pressures.

Reducing environmental impact of buildings using bio-based materials

Bio4EEB project’s strays away in its approach from waste recovery in the construction sector, as in the other sister projects, to promote bio-based materials from natural sources, especially Posidonia oceanica (Neptune seagrass) found on Mediterranean beaches. The intention is to reduce the energy demand of buildings by using insulation panels made of Posidonia, a bio-based material.

Bio4EEB representative Eva Coscia said, “We have approached from a different perspective because we are not recycling waste coming from the construction sector, but we are offering to this sector new products, new materials that are coming from unused, natural-based products, so like recycled Posidonia, or recycled rice scraps.”

In the project, data from real-life use cases from five countries of Lithuania, Germany, France, Czechia and Spain will be used alongside 3 virtual demo cases and fed into a comprehensive platform and Life Cycle Analysis (LCA) conducted to assess the environmental impact of new materials in relation to traditional insulation materials.

The end objective, according to Eva Coscia, representative of Bio4EEB project, is to reuse materials from nature as much as possible to increase circularity and reduce the carbon footprint through this strategy. But the real challenge, Coscia concludes, “is getting stakeholders to switch to new materials”. For this to work, Coscia said, “we need to engage local operators, communities and governments.”

Lack of standardisation a stumbling block?

During the discussions, standardisation became a hot topic, with all projects agreeing that there is a lack of clear, harmonised and comparable standards for circular materials in Europe. The representatives called for an urgent need to draw up unified, and practical standards for real circularity across sectors.

Here’s what the projects said:

BIO4EEB – “We’re working on standardisation, certifications, clear knowledge about tests – so that new materials can be easily compared to traditional materials – there’s still a gap.”

ReBoat Project – “Textiles are not well structured in terms of waste management; we need clearer standards but also performance, EU countries are not aligned; homogeneous standardisation needed.”

EcoReFibre – “In wood sector, a lot of talk about harmonisation, but we need to pay attention towards making it easier to recycle products; for example, ban materials that make recycling difficult; division of what has to be burned and what recycled – and create market that can work across borders.”

Wood2Wood Project – “Companies don’t know the standard that needs to be applied; changing terminologies can help to improve standards; another issue is how to compare materials, because they have different standards.”

In the end, all projects agreed that a long-term vision for scaling solutions beyond individual pilot cases to market-ready cases is a precondition to achieve the circularity ambitions of the EU. Crucially, technology alone won’t get us to where we want to go, but engaging a multitude of stakeholders from citizens, policymakers, industry, civil society can drive systemic change.