Construction, food and travel sectors drive around 30% of environmental pressures.

But in these sectors bio-based alternatives exist with a significant decarbonisation potential.

A sustainable bioeconomy can reduce pressures on virgin resources through circular use of domestic biomass.

Levery, one of Wood2Wood’s consortium partners, is helping to support sustainable transformation in the construction sector by demonstrating and validating the use of wood-based materials in actual building components.

Team Levery is working to integrate PLA wood-based materials developed by UPV/EHU and National Technical University of Athens into prefabricated façade systems.

In the recent months, progress has been made in three core areas:

– 𝗖𝗼𝗺𝗽𝗮𝗿𝗮𝘁𝗶𝘃𝗲 𝗽𝗿𝗼𝗱𝘂𝗰𝘁 𝗮𝗻𝗮𝗹𝘆𝘀𝗶𝘀: evaluating the market potential of bio-based alternatives.

– 𝗗𝗲𝘀𝗶𝗴𝗻 𝗼𝗳 𝘁𝘄𝗼 𝗽𝗮𝗻𝗲𝗹 𝘁𝘆𝗽𝗲𝘀, which are now entering the production phase by Bloom Biorenewables:

(1) solid panel to replace gypsum board, cement board or OSB;

(2) a lightweight honeycomb panel designed to enhance acoustic absorption for interior applications;

– 𝗙𝗮𝗰̧𝗮𝗱𝗲 𝘀𝘆𝘀𝘁𝗲𝗺 𝗲𝗻𝗴𝗶𝗻𝗲𝗲𝗿𝗶𝗻𝗴, leveraging these new panels in a modular building envelope concept.

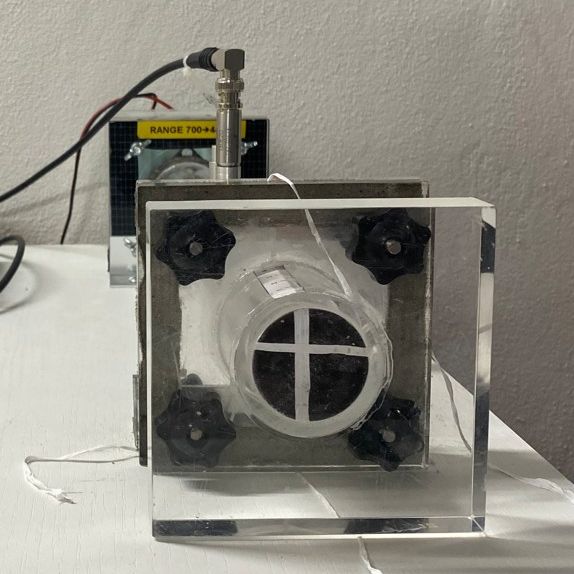

Initial impedance tube tests are underway to validate acoustic performance and confirm the assumptions made during the design phase. These early evaluations will inform further refinements and help to ensure that product development is aligned with real construction requirements.

Our aim is to transition from bio-waste, such as wood, to construction materials that meet technical performance criteria while contributing to circular value chains.

This represents a significant step forward in the development of experimental materials into viable, market-ready solutions which we are planning to integrate into prefabricated facade system.

Integrating wood-based materials and applying them in demonstrators is part of our broader strategy to make bio-based construction scalable, competitive and compliant with evolving industry standards.